EUROPELEC est le spécialiste français de la conception, la fabrication, l’installation et la maintenance des équipements pour le traitement des eaux usées urbaines et industrielles. La société est leader sur le marché français et exporte dans plus d’une quarantaine de pays les produits issus de ses usines, situées à proximité de Paris.

EUROPELEC a développé plusieurs gammes de produits afin de couvrir l’ensemble des besoins des clients existants ainsi que leurs spécificités propres.

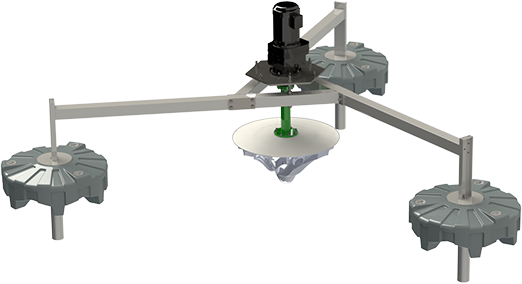

Première entreprise à fabriquer en France ses turbines (1983) et ses diffuseurs (au tournant des années 2000), Europelec a toujours placé l’ingénierie et l’innovation au cœur de ses préoccupations.

Please fill in the following form to upload documents.

Partager